Microplastics are plastic particles less than five mm in diameter. They can occur from the degradation of large plastic waste (secondary) or from primary sources including:

- The scrubbing agents in personal care products (micro-beads, shower gels, creams etc.)

- The abrasion of large plastic objects during manufacturing, use or maintenance (such as the abrasion of synthetic textiles during washing).

THE EXTENT OF THE PROBLEM

According to a recent study by the International Union for the Conservation of Nature (IUCN):

- 9.5 million MT of new plastic waste enters the ocean each year

- Between 15 and 31 per cent of all of the plastic in the oceans could originate from primary sources.

INDUSTRY RESEARCH INTO THE PROBLEM

A literature review carried out by Patagonia and the University of California, and published in the report ’Microfiber Pollution and the Apparel Industry’ revealed that:

- Finished apparel products contain large quantities of chemical substances from processing and finishing steps in garment manufacturing, many of which are released from garments during consumer washing.

- Wastewater treatment plants receive large amounts of microfibers daily. While most of these microfibers are removed, a significant amount is still released into the local environment.

- Analysis of global water and sediment sampling data indicates that microfibers are ubiquitous in aquatic environments. Recent evidence supports microfiber pollution pervading terrestrial environments and the atmosphere as well.

- Aquatic organisms throughout the food chain consume microplastics and microfibers both directly and indirectly. Within the food chain, these particles have been found to cause physical and chemical impacts, resulting in starvation and reproductive consequences in species.

- Microplastics and microfibers have also been found in marine species directly consumed by humans, the effects of which are unknown.

- They have also been found in abiotic ocean products such as sea salt.

The report recommended the apparel industry looked into the effects of garment construction, washing machine type and fabric composition, use of recycled polyester and biodegradable synthetic textiles, and the possibility of re-incorporating fibers shed in the consumer washing phase in garment manufacturing.

The above extract was taken from the Textile Exchange Prefered Fiber Materials Market Report 2017

Click here for more information on the depth of the plastics problem, from Cotton Incorporated

WHAT ABOUT COTTON?

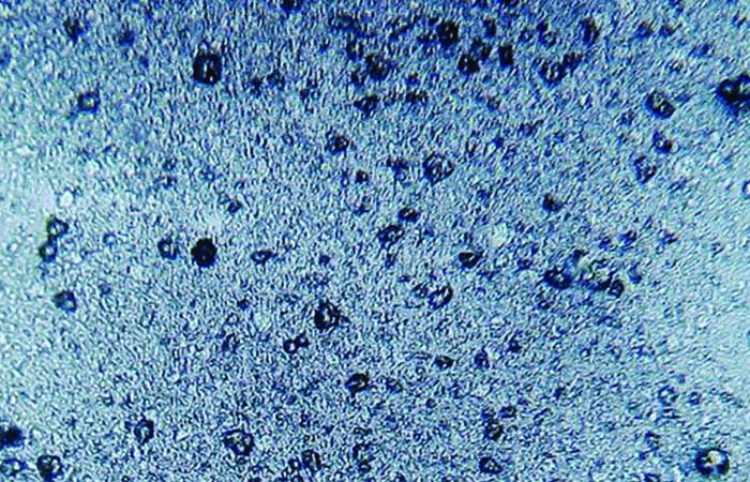

As the issue of microplastic pollution has become a key topic for the textile industry, Australia's Cotton Research and Development Corporation in partnership with Cotton Incorporated, funded a study to examine this issue for cotton as opposed to other fabrics.

The study was conducted by the North Carolina State University and examined how many microfibers were generated from laundering different fabrics, and their subsequent biodegradability.

It found that cotton and rayon (viscose) fabrics release more of these minute, problematic fibres during laundering than polyester textiles; but it was also found that in a wastewater treatment situation, the biodegradation of natural textile fibres is markedly more rapid than that of synthetics.

After 220 days in an aquatic environment, the cotton had 74% degradation, rayon 61% and polyester had just 6% degradation after 220 days.

The biodegradation results indicate that natural-based microfibres such as cotton and rayon can be degraded during the wastewater treatment process and in natural aquatic environments. Even though the polyester fabrics released less microfibres than the other fabric types tested, these microfibres are expected to persist in the environment for long periods of time.

Click here for more information on cotton's biodegradability.